Personal computing discussed

Moderators: askfranklin, renee, emkubed, Captain Ned

notfred wrote:For hooking it up I'd be concerned about the AC flowing through the controller, I think it would be better to add the equivalent of C2 from the Relco circuit.

notfred wrote:For hooking it up I'd be concerned about the AC flowing through the controller, I think it would be better to add the equivalent of C2 from the Relco circuit.

notfred wrote:104K is 0.1uF +-10% http://jswatson.net/electronics/CapConv.html

The 2A is probably temperature and voltage rating but finding which particular chart is used could be tricky. In your case I'd just go to 400V or maybe even the next one up given 385V output from the circuit.

liquidsquid wrote:

What worries me is modern trains on this system discharging HV spikes into the motors and potentially static sensitive controllers in the engines. Not the best thing to do to sensitive electronics.

For fun when I get home I will throw together an LTSpice simulation, but I am swamped.

anotherengineer wrote:

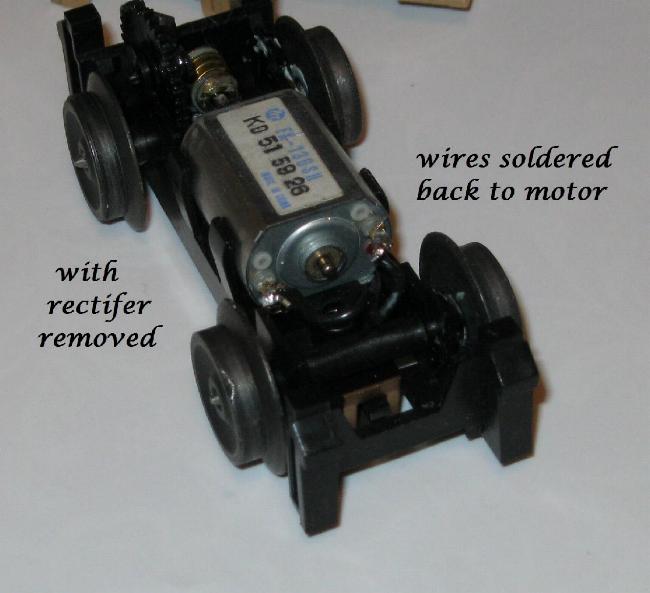

jprampolla wrote:Ah, that's modern stuff for me, most of my motors are derivations on http://www.tri-ang.co.uk/OONew/X04.htm or http://www.tri-ang.co.uk/OONew/chassisB ... rBogie.htmThe motors in my equipment are very simple DC can motors, not expensive, and there isn't any kind of circuit, not even a diode or a capacitor, just the motor connected to wheel contacts, or wheels and center rail wipers for the 3 rail O gauge.

notfred wrote:jprampolla wrote:Ah, that's modern stuff for me, most of my motors are derivations on http://www.tri-ang.co.uk/OONew/X04.htm or http://www.tri-ang.co.uk/OONew/chassisB ... rBogie.htmThe motors in my equipment are very simple DC can motors, not expensive, and there isn't any kind of circuit, not even a diode or a capacitor, just the motor connected to wheel contacts, or wheels and center rail wipers for the 3 rail O gauge.

I'm surprised you say there is no capacitor in there, my old ones have a cap that I think is meant to stop them acting as a spark-gap transmitter and just coincidentally will help short out the oscillator in the Relco.

Version 4

SHEET 1 2116 680

WIRE 784 -288 592 -288

WIRE 784 -240 784 -288

WIRE 80 -224 -32 -224

WIRE 944 -224 832 -224

WIRE 368 -192 208 -192

WIRE 528 -192 368 -192

WIRE 592 -192 592 -288

WIRE 592 -192 528 -192

WIRE 848 -176 832 -176

WIRE 208 -160 208 -192

WIRE 368 -160 368 -192

WIRE 848 -144 848 -176

WIRE -288 -128 -304 -128

WIRE -176 -128 -288 -128

WIRE 80 -128 80 -144

WIRE 80 -128 -176 -128

WIRE -288 -112 -288 -128

WIRE -176 -112 -176 -128

WIRE 944 -112 944 -144

WIRE 80 -96 80 -128

WIRE 784 -96 784 -160

WIRE 784 -96 672 -96

WIRE 784 -80 784 -96

WIRE 816 -80 784 -80

WIRE 208 -64 208 -80

WIRE 368 -64 368 -96

WIRE 368 -64 208 -64

WIRE 528 -64 368 -64

WIRE 592 -64 528 -64

WIRE 784 -48 784 -80

WIRE -176 -32 -176 -48

WIRE 672 -32 672 -96

WIRE -288 0 -288 -32

WIRE 80 32 80 -16

WIRE 592 64 592 -64

WIRE 672 64 672 32

WIRE 784 64 784 32

WIRE 784 64 672 64

WIRE 784 80 784 64

WIRE 80 112 80 96

WIRE -32 160 -32 -224

WIRE -16 160 -32 160

WIRE 592 176 592 144

WIRE 80 208 80 192

WIRE 80 208 48 208

WIRE -16 256 -32 256

WIRE 80 256 80 208

WIRE 80 352 80 320

WIRE -32 480 -32 256

WIRE 80 480 80 432

FLAG 80 480 0

FLAG 528 -192 TRAX_P

FLAG 528 -64 TRAX_N

FLAG -32 480 0

FLAG -176 -32 0

FLAG -288 0 0

FLAG 592 176 0

FLAG 784 80 0

FLAG 944 -112 0

FLAG 848 -144 0

FLAG 816 -80 MOTOR_P

SYMBOL npn 48 160 M0

WINDOW 3 56 68 Invisible 2

WINDOW 38 56 96 Left 2

SYMATTR Value ""

SYMATTR SpiceModel bu406

SYMATTR InstName Q1

SYMBOL ind2 64 -112 R0

SYMATTR InstName L1

SYMATTR Value 30µ

SYMATTR Type ind

SYMBOL ind2 64 -240 R0

SYMATTR InstName L2

SYMATTR Value 120µ

SYMATTR Type ind

SYMBOL ind2 224 -176 M0

SYMATTR InstName L3

SYMATTR Value 1000µ

SYMATTR Type ind

SYMBOL cap 64 32 R0

SYMATTR InstName C1

SYMATTR Value 10nF

SYMBOL res 64 96 R0

SYMATTR InstName R1

SYMATTR Value 1.5K

SYMBOL diode 96 320 R180

WINDOW 0 24 64 Left 2

WINDOW 3 24 0 Left 2

SYMATTR InstName D1

SYMATTR Value 1N4148

SYMBOL res 64 336 R0

SYMATTR InstName R2

SYMATTR Value 4.7K

SYMBOL cap 352 -160 R0

SYMATTR InstName C2

SYMATTR Value 1nF

SYMBOL cap -192 -112 R0

SYMATTR InstName C3

SYMATTR Value 10n

SYMBOL voltage -288 -128 R0

WINDOW 123 0 0 Left 2

WINDOW 39 0 0 Left 2

SYMATTR InstName V1

SYMATTR Value 16

SYMBOL voltage 592 48 R0

WINDOW 123 0 0 Left 2

WINDOW 39 0 0 Left 2

SYMATTR InstName V2

SYMATTR Value 16V

SYMBOL ind 800 48 R180

WINDOW 0 36 80 Left 2

WINDOW 3 36 40 Left 2

SYMATTR InstName L4

SYMATTR Value 1000µ

SYMATTR SpiceLine Rser=10

SYMBOL sw 784 -144 R180

SYMATTR InstName S1

SYMATTR Value MySwitch

SYMBOL voltage 944 -240 R0

WINDOW 123 0 0 Left 2

WINDOW 39 0 0 Left 2

SYMATTR InstName V3

SYMATTR Value PULSE(1 0 10m 1n 1n 1m 25m)

SYMBOL cap 656 -32 R0

SYMATTR InstName C4

SYMATTR Value 1n

TEXT 1200 -72 Left 2 !**************************************\n* Model Generated by MODPEX *\n*Copyright(c) Symmetry Design Systems*\n* All Rights Reserved *\n* UNPUBLISHED LICENSED SOFTWARE *\n* Contains Proprietary Information *\n* Which is The Property of *\n* SYMMETRY OR ITS LICENSORS *\n* Modeling services provided by *\n* Interface Technologies www.i-t.com *\n**************************************\n.MODEL bu406 npn\n+IS=3.31042e-11 BF=40.9297 NF=0.85 VAF=23.6173\n+IKF=9.89434 ISE=4.75e-12 NE=3.46875 BR=2.17748\n+NR=1.5 VAR=19.8032 IKR=10 ISC=3.25e-12\n+NC=3.65625 RB=2.68547 IRB=0.101586 RBM=0.1\n+RE=0.0001 RC=0.198649 XTB=0.128676 XTI=1.18913\n+EG=1.17512 CJE=6.29276e-10 VJE=0.651734 MJE=0.35309\n+TF=4.49798e-09 XTF=1.35722 VTF=0.995767 ITF=0.999981\n+CJC=2.66401e-10 VJC=0.409483 MJC=0.371615 XCJC=0.803125\n+FC=0.533467 CJS=0 VJS=0.75 MJS=0.5\n+TR=1e-07 PTF=0 KF=0 AF=1\n* Model generated on Jan 31, 2004\n* Model format: SPICE3

TEXT 254 448 Left 2 !.tran 100m startup

TEXT 400 104 Left 2 ;Train Power

TEXT 88 -264 Left 2 !K1 L1 L2 L3 1

TEXT 816 0 Left 2 ;Motor inductance

TEXT 1008 -192 Left 2 ;Track Fault

TEXT 1200 616 Left 2 !.model MySwitch SW(Ron=.1 Roff=1Meg Vt=0.5 Vh=-.25)

liquidsquid wrote:Spoilsport! Nobody would get their fingers zapped that wayIt needs a means to only turn on when there is a load on V2 (motor present) and turn off when there is not with some delay to differentiate between dirt and no train.

liquidsquid wrote:As promised, here is the simulation of the circuit.

The circuit needs some enhancements to limit the output voltage, and to protect Q1 from damage. It is a little too simple, but at the time of design, this was how designs were done. It needs a means to only turn on when there is a load on V2 (motor present) and turn off when there is not with some delay to differentiate between dirt and no train.

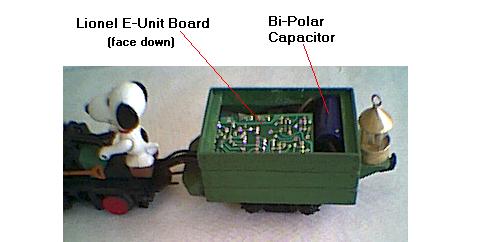

liquidsquid wrote:Another trick you could employ is use some larger bipolar electrolytic capacitors inside of the engines and other motorized devices that will keep the motors running long enough to get over the dirty spots. The capacitor needing charge after a dirty spot will certainly wet the track. If you can fit it in there. Values in the 4700uF range would be adequate. Bipolar is a must though as most electrolytics cannot be connected backwards without serious problems, like the train car blowing up.